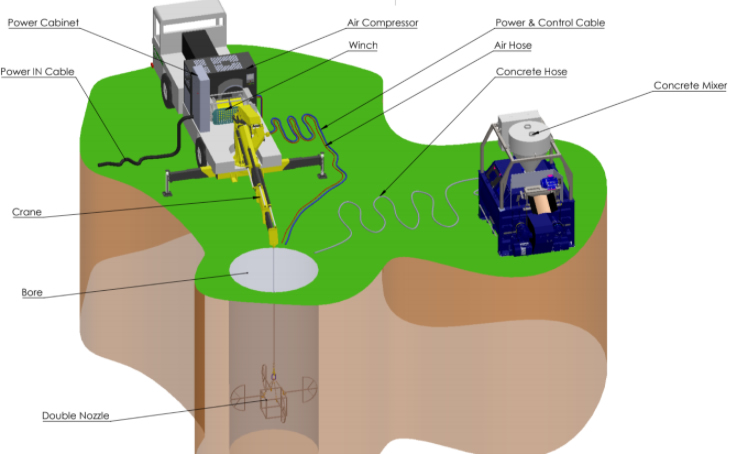

STI Raise Liner

The STI Raise Shotcrete Liner is a self-contained unit that includes a hydraulic crane, air compressor and winch. All mounted on a heavy duty mine carrier. Also included but not mounted on the truck is a Pan Mixer, Concrete Pump and a one cubic meter accelerator tote with accelerator pump. The later are set up in front of the truck for easy loading of the pan mixer.

The advantage of this unit is it can driven to an underground location and set up next to

the Raise. It then only needs to be hooked up to the Mine Power and Water. The 300 CFM

Compressor supplies plenty of air at 150 PSI.

The winch has a VFD controlled motor to compensate for changing diameter of the drum

on different wraps, insuring correct speed of the robot and a wide range of speeds. It also

is equipped with Dynamic breaking and and Positive Lock parking break.

The winch, pump and accelerator pump are all controlled by a PLC. This insures the

quality and thickness of the shotcrete liner installed. The PLC will also allow for different

applications such as bad ground areas where possibly a thicker application is necessary or

wet areas where a lighter coat with more accelerator is required.

The mix is produced by a pan mixer, the mixer has 3,000 lb concrete batch capacity it will

mix a 2200 lb super sack in three minutes (subject to density of material). The mixer then

quickly discharges the material into the pump hopper. Once the mixer is empty and the

pump hopper is full, it can mix another load while the pump is working on whats in the

hopper. Therefor the robot has a continuous supply of material.

While other systems can spray shotcrete on the walls of the raise the quality is anyones

guess. Our system insures that the required amount is applied. Once the application is

finished the robot can be lowered again, scan the raise and take a video of the finished

product. This can also be done before the application if fallouts or water is suspected. If

problem areas are detected they can be dealt with appropriately.